This fact can be verified by experimenting with different values of. However, also recall that increasing often results in increased overshoot, therefore, it appears that not all of the design requirements can be met with a simple Recall from the Introduction: PID Controller Design page that increasing the proportional gain will reduce the steady-state error. Title('Step Response with Proportional Control')įrom the plot above we see that both the steady-state error and the overshoot are too large.

In the figure below, annotations have specifically been added for Settling Time, Peak Response, and Steady State. You can view some of the system's characteristics by right-clicking on theįigure and choosing Characteristics from the resulting menu. You should generate the plot shown below. Add the following commands to the end of your m-file and run it in the command Now let's examine the closed-loop step response. Add the following code to the end of your m-file. To determine the closed-loop transfer function, we use the feedback command.

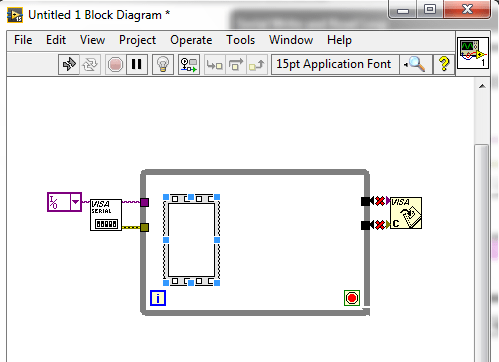

Let's first try employing a proportional controller with a gain of 100, that is, C( s) = 100. Recall that the transfer function for a PID controller is: Create a new m-file and type in the following commands. Now let's design a controller using the methods introduced in the Introduction: PID Controller Design page.

0 kommentar(er)

0 kommentar(er)